Infrared Honeycomb Ceramic

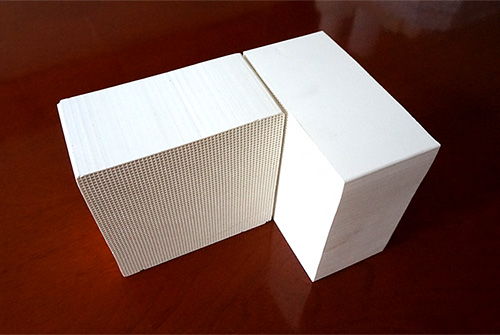

Ceramic Honeycomb materials function mainly as the catalyst support/carrier, heat exchange media, Ceramic filter plate for cast/foundry, ceramic tile for infrared heaters and High alumina honeycomb ceramic plate/slice filters for sulfur removal/recovery. JINTAI Ceramic Honeycomb with Cell structure density rangeing from 10 to300cpsi/400cpsi/600cpsi(CPSI means cells per square inch). Ceramic Honeycomb Material are typically available in cordierite, mullite and alumina etc on customer request.

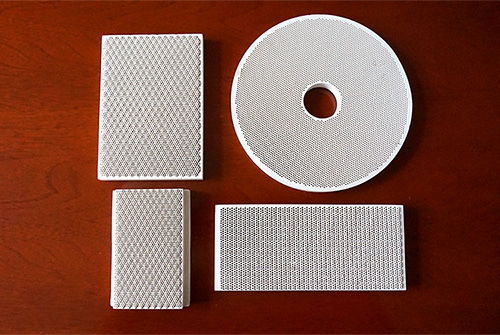

Honeycomb ceramics block available shapes: rectangular, cylinder or ellipse. Cell shapes in square, circle, hexagonal, triangle etc. The specification list in the website is just a part of our available specifications for your reference. We can also customized the production based on your drawing and samples.

Honeycomb infrared ceramic plate for gas heater burner is made by the high purity cordierite material and used in the gasfired stove. This product has good thermal shock resistance ( no cracks on the product if the honeycomb ceramic with 1000 is in the water with 20 for 3 times ). infrared combustion ceramic plate also has high mechanical strength ( crushing strength is 20MPa on the top and 5MPa on the side), good endurance forhigh temperature, high resistance for erosion.

Infrared ceramic plate,infrared ceramic honeycomb can be applied to different gas. When customer makes the order for it, he or she should provide the parameters such as the product size, CPSI, cell shape, the gas style, the shape on the upper side. If the customer needs the one with coated catalyst, please provide the catalyst color.

Physical characters:

Good thermal shock resistance ( no cracks after 3 times thermal shock from 800 °C to cold water)

High mechanical strength ( crushing strength is 20MPa on the top and 5MPa on the side), good endurance for high temperature.

High resistance for erosion.

Advantages:

1. Save 20-50% energy consumption.

2. Burn without flame, low noise.

3. Reduce the formulation of such harmful gas as CO, NOx, etc by a large margin (more than 70%).

4. Strong bearing of wind, using safely.

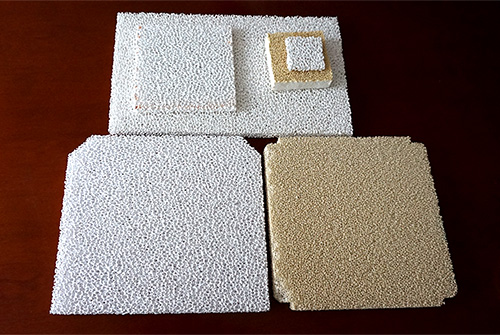

Infrared catalytic burner is a porous ceramic honeycomb panels attached to the catalyst as a burning stove, made use of advanced science and technology design. As a result of the ideal combustion - catalytic combustion of methane gas can be more fully combustion, maximize the energy of the gas, while also reducing flue gas pollution (CO < 0.02% of NOx < 10 ppm), completely to meet national environmental standards; catalytic combustion but also to eliminate the infrared combustion prone to coking phenomenon, to effectively extend the life of the burner; our catalytic combustion in the hole of the porous ceramic honeycomb board, it is true flameless combustion, produce most of the energy released in the form of infrared radiation, infrared has a strong penetration can stimulate the resonance of water molecules, so that the heat to penetrate into the depths of the object to be heated evenly. in order to ensure uniform heating effect to achieve the purpose to improve the heating quality and drying efficiency.

Infrared Honeycomb Ceramic Plate, mainly for gas-fired infrared burners. Such a ceramic plate by honeycomb ceramic plate surface to improve the simple planar corrugated staggered three-dimensional, increasing the specific surface area and combustion area, which play a regenerative combustion role to achieve more complete combustion flame seedlings to reach the infrared burner heating effect, in order to achieve low power consumption and high environmental requirements. Overcome the planar flame in the combustion of the gas is too long, burning inadequate, resulting in high energy consumption, emissions low enough to deficiencies.

Infrared honeycomb ceramic burner plate.

Infrared burner has the following characteristics.

1. Use of liquefied petroleum gas, clean, environmentally friendly.

2. High thermal efficiency, economical and practical, the cost of gas consumption than the power consumption savings of 50%.

3. Install a convenient and simple. Compared with the electric dryer, reduce costs by more than half.

Therefore, using the infrared burner has become the industrial heating, drying, thermal insulation of a new technology, new vigorous, it has been widely used in industrial paint, printing and dyeing, food and other industries and fields.

Typical applications

1. Bake furnace

2. Food baking production line computer automatic dryer

3. Dedicated gas infrared oven

4. Food grilled cabinet

5. Food baking line

6. Spray the bottom of the production line installation

We produce honeycomb ceramic infrared radiation effect, high strength, combustion does not change color, not coke, burning fireworks hole to plug, no glitches, uniform pore size, ignition and burning half a minute into the infrared effects, ceramic burning a hours after watering not rupture, the burning area established by the BTU.

We are instrumental in providing to our valuable customers excellent quality Infrared Honeycomb Ceramic Plate for Burners.

English

English Español

Español Français

Français Русский

Русский