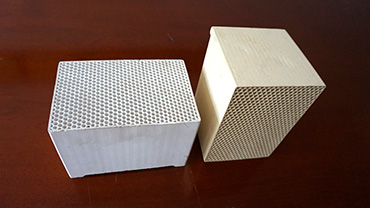

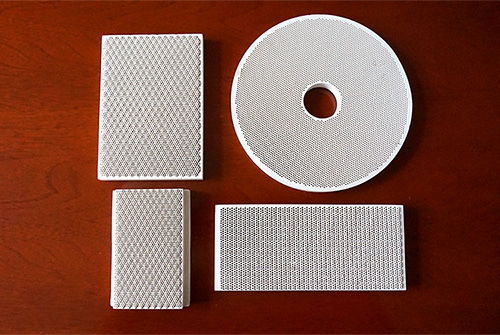

Honeycomb Blocks for Heater Exchanger

Regenerative high temperature air combustion (referred to as HTAC) is a huge energy-saving and environmental efficacy of new combustion technology. Honeycomb ceramic regenerator is a key component of regenerative burner is widely used in iron and steel, machinery, building materials, petrochemicals, nonferrous metal smelting and other industries, furnace, hot air furnace, heat treatment furnace, cracking furnace, baking, melting furnace, both in the hot furnace, oil and gas boilers, and furnaces. The technique is to make two regenerator alternating endothermic exothermic by reversing device, the limited recovery of the flue gas heat, and then the furnace combustion air and gas is heated to above 1000 ℃, even the low calorific value of low-grade fuel to achieve stable ignition and efficient combustion, the fuel savings of 40-70%. Production increased by 15% and the billet oxidation burning down more than 40%, NOx emissions of less than 100ppm, emissions from the flue gas temperature below 150 ° C, greatly reduces the greenhouse effect of Earth's atmosphere. If most of the national industrial furnace use HTAC technology, the economic and social benefits is unlimited, will greatly ease the energy shortage situation, and to improve the human living environment.

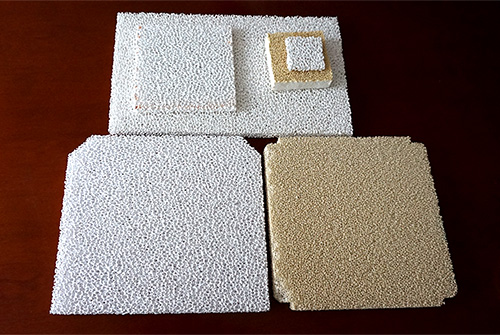

Honeycomb ceramics, thermal storage ball and regenerator tube three kinds regenerator. The specific surface area of the honeycomb ceramic ball 5 times more than 4-5 times of the heat transfer capability, resistance to airflow is only 1/3 of the ball diathermy depth small. Therefore, the ceramic honeycomb regenerative ball is more conducive to oxygen combustion furnace temperature uniformity and heat transfer rate, fast out of steel, greatly reduce oxidative damage and NOx gases generated, and significantly improve environmental protection and energy saving effect. Honeycomb ceramic regenerator volume is greatly reduced, and can be arranged in a sufficient amount of the burner to meet the needs of the heat load. Compared to the straight flow channels of the honeycomb ceramic, ball channel difficult to plug, self-cleaning, burning unclean characteristics suitable for our country. Newly developed mullite, cordierite synthetic corundum honeycomb ceramic regenerator with a high temperature, corrosion resistance, good thermal shock resistance, high strength, regenerative heat, good thermal conductivity and other significant advantages, energy-saving performance and service life is greatly improved, favored by the steel industry.

At present, our products have already been approved by numerous iron and steel enterprise and exported to Japan, South Korea and Europe and America market.

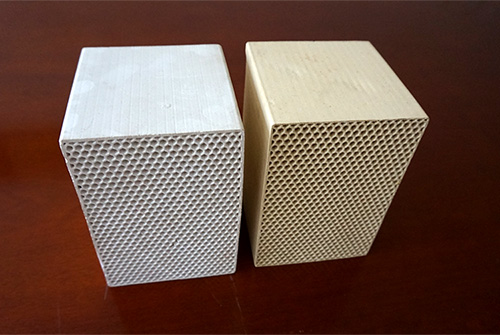

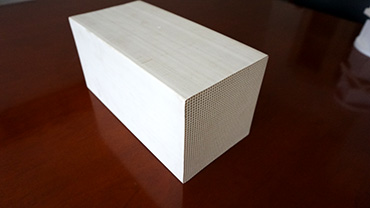

The commonly used honeycomb heat accumulators are generally 100 x 100 x 100mm, 150 x 100 x 100mm, and the grid holes are generally 3 x 3mm, and the wall thickness is 0.9-1mm. We can manufacture according to customer's requirements.

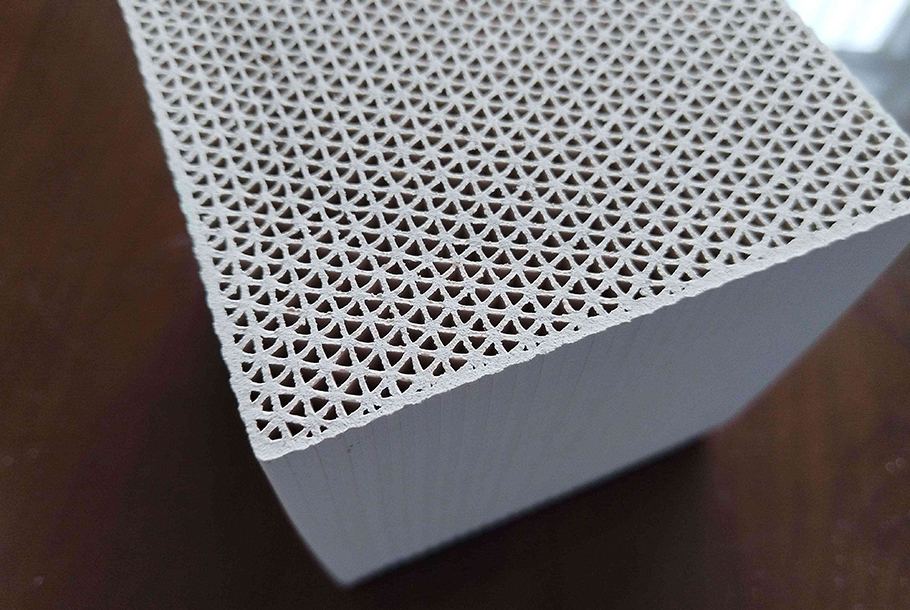

- Specifications Hex Hole Honeycomb Ceramic Regenerator:

Dimensions |

Pore size |

Wall Thickness |

Heat Transfer Area |

Porosity |

150×100×100 |

3.1 |

1.0 |

673 |

53 |

150×100×100 |

3.1 |

1.5 |

625 |

49 |

150×100×100 |

3.5 |

1.0 |

655 |

58 |

150×100×100 |

3.9 |

1.1 |

624 |

58 |

100×100×100 |

3.1 |

1.0 |

673 |

53 |

100×100×100 |

3.5 |

1.0 |

655 |

58 |

100×100×100 |

3.9 |

1.1 |

624 |

58 |

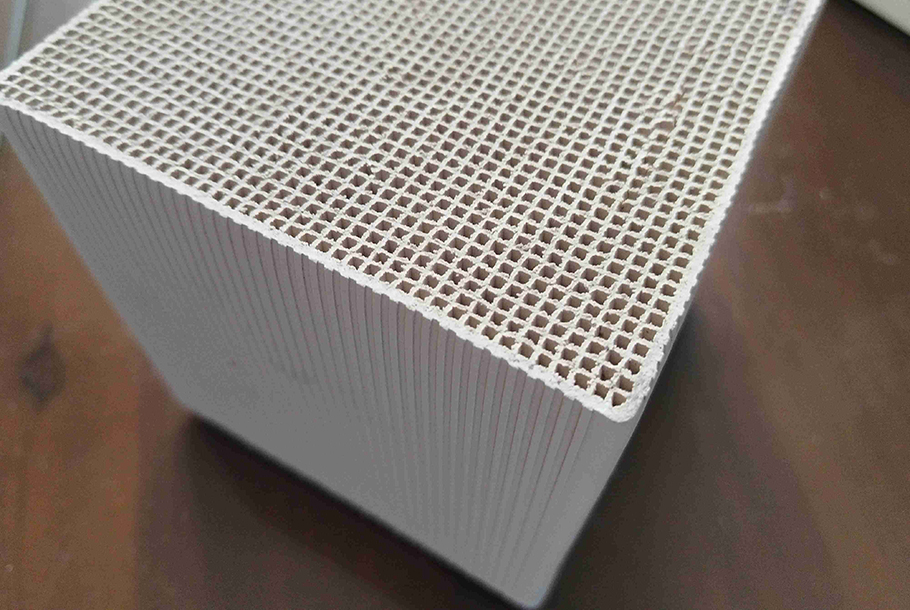

- Specifications of Square Hole Honeycomb Ceramic Regenerator:

Dimensions |

Pore size |

Wall Thickness |

Heat Transfer Area |

Porosity |

150×100×100 |

2.5 |

1.0 |

784 |

49 |

150×100×100 |

3.0 |

1.1 |

691 |

52 |

150×100×100 |

5.0 |

2.0 |

329 |

49 |

100×100×100 |

2.5 |

1.0 |

784 |

49 |

100×100×100 |

3.0 |

1.1 |

691 |

52 |

100×100×100 |

5.0 |

2.0 |

329 |

49 |

English

English Español

Español Français

Français Русский

Русский