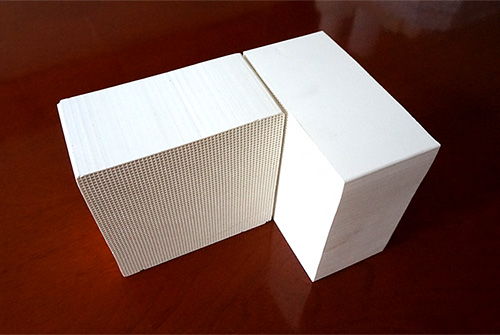

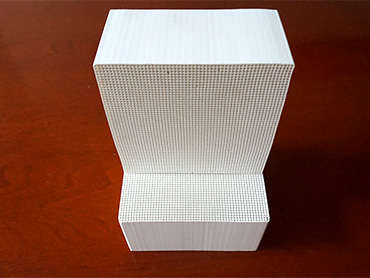

Honeycomb Substrate

The honeycomb substrate, also called support, is one of the components of the supported catalyst. The catalytically active component is supported on the surface of the carrier, the carrier is mainly used to support the active component, so that the catalyst has a specific physical property, and the carrier itself generally does not have catalytic activity.

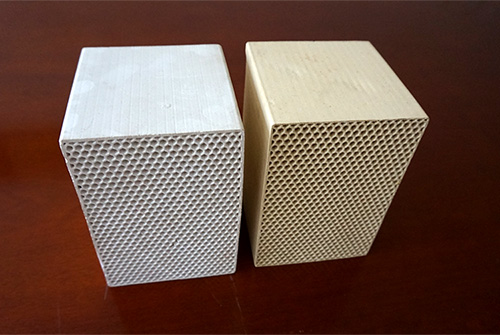

The honeycomb substrate is mainly used in the automotive and other high-temperature process exhaust. The main material is cordierite, after coated the catalyst, catalytic conversion of the exhaust, so as to achieve the national emission standards. It has characteristics of large surface area, small expansion coefficient, high strength, high water absorption, and good matching with the catalytic active component, heating up fast and so on.

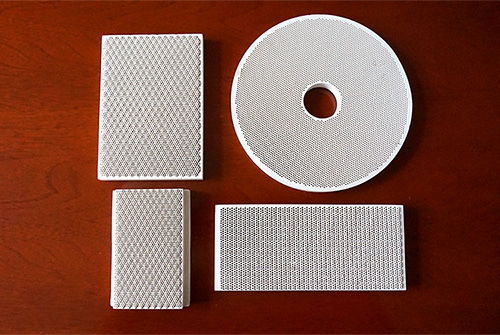

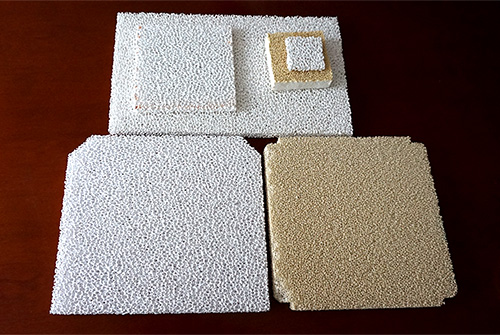

Honeycomb ceramic as a Honeycomb Substrate is an efficient carrier and can achieve good results in specific applications. For example: photo-catalysis, fresh air system, ventilation systems.

Product size can be customized according to customer needs.

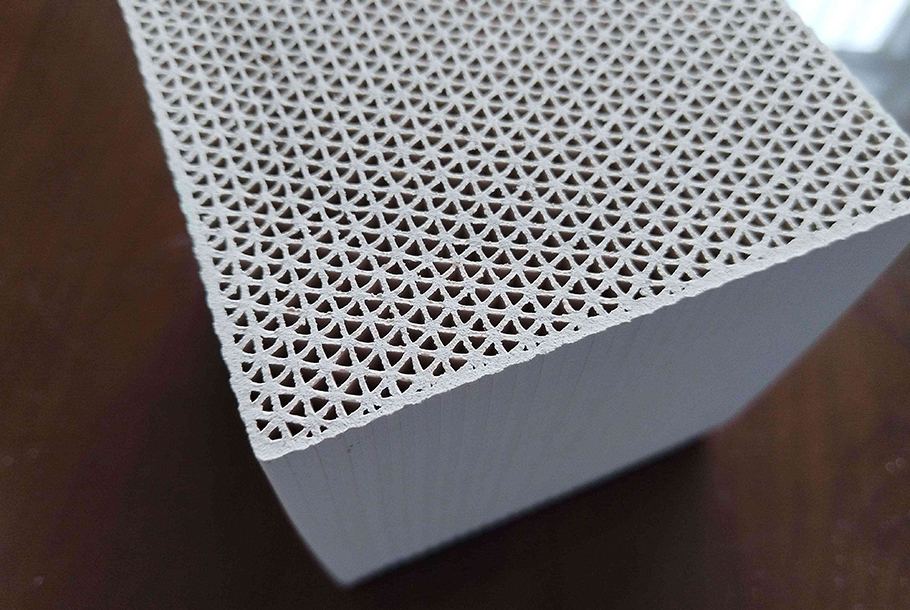

- Characteristics:

1. Large specific surface area: to ensure full access to the exhaust gas with the catalyst;

2. Stable water absorption: to ensure the catalyst evenly firmly attached to the surface of the honeycomb substrate.

3. Warm-up: after start-up the engine, the temperature of the carrier can reach the catalyst activation temperature in the shortest possible time.

4. Low exhaust resistance: the engine's exhaust resistance is small, to ensure that doesn't affect the engine performance.

5. High strength: the operating environment of the honeycomb substrate is in the bumpy car, so the honeycomb substrate must be high strength without being external damage.

6. Good assembly: the carrier is an exhaust assembly parts, only good appearance and precise dimensions can ensure perfect assembly.

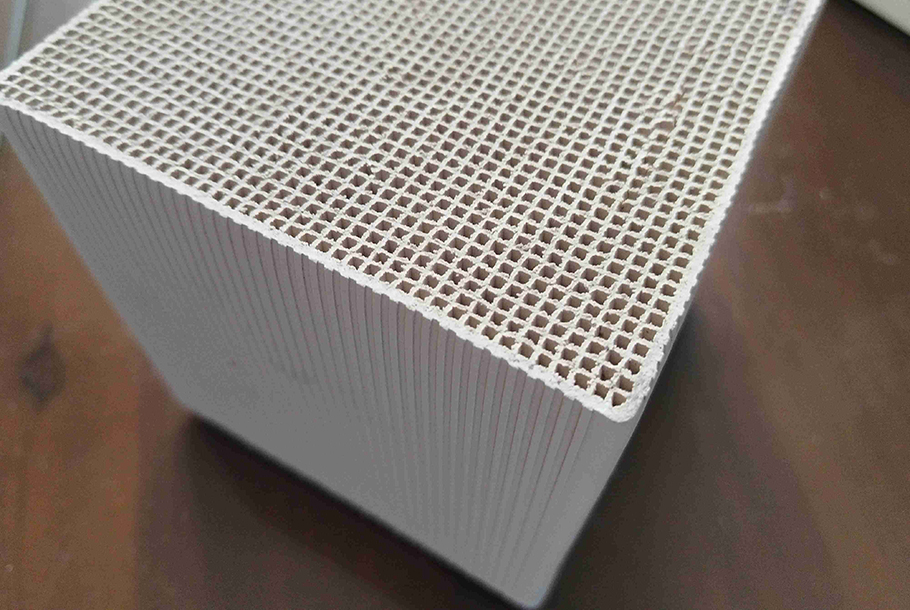

- Technical Data Sheet:

Name |

Index |

Tolerance Range |

Wall Thickness |

0.17mm |

0.03mm-0.02mm |

Volume Weight |

≤460G/L |

±60G/L |

Outside Dimension |

25-100mm |

±1mm |

100-15mm |

≤±1% |

|

Perpendicularity |

|

≤1.0%(height) |

Depth of Parallelism |

|

≤1.0%(height) |

Mesh Number |

200mesh, 300mesh, 400mesh |

|

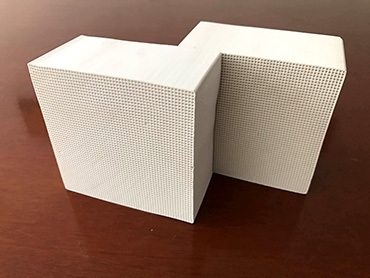

- Physical and Chemical Properties:

Name |

Unit |

Index |

|

Chemical Composition |

Al2O3 |

% |

35.1±1.6 |

MgO |

% |

13.5±1.5 |

|

SiO2 |

% |

50.0±1.8 |

|

Compression Strength |

A-axis |

Mpa |

≥15.0 |

B-axis |

Mpa |

≥3.0 |

|

C-axis |

Mpa |

≥0.15 |

|

Coefficient of Thermal Expansion (20-800℃) |

℃ |

≤1.5*10-6 |

|

Soften Temperature |

℃ |

≤1410 |

|

Thermal Shock Resistance |

℃ |

≤550℃ |

|

Water-absorbingrate |

% |

24±4% |

|

Cordierite CrystalContent |

% |

≥90 |

|

Open Area |

% |

≥70% |

|

English

English Español

Español Français

Français Русский

Русский