Honeycomb Substrate

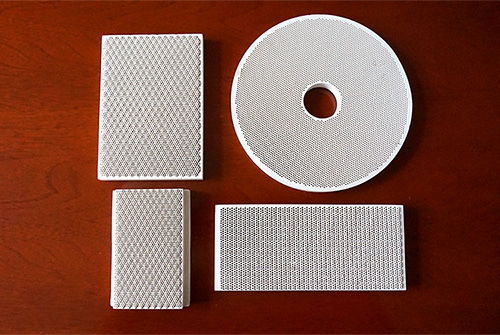

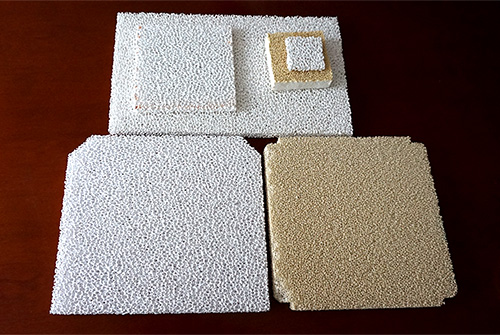

Ceramic Honeycomb materials function mainly as the catalyst support/carrier, heat exchange media, Ceramic filter plate for cast/foundry and High alumina honeycomb ceramic plate/slice filters for sulfur removal/recovery. JINTAI Ceramic Honeycomb with Cell structure density rangeing from 10 to300cpsi/400cpsi/600cpsi(CPSI means cells per square inch). Ceramic Honeycomb Material are typically available in cordierite, mullite and alumina etc on customer request.

Honeycomb ceramics block available shapes: rectangular, cylinder or ellipse. Cell shapes in square, circle, hexagonal, triangle etc. The specification list in the website is just a part of our available specifications for your reference. JINTAI can also customized the production based on your drawing and samples.

Catalyst converter honeycomb ceramics:

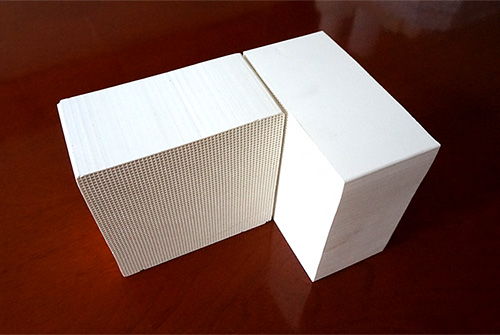

As a special kind of chemical reaction device, the catalyst converter is used for the control of automobile exhaust emissions with the ceramic substrate as its key part. Now the world recognized kind is the honeycomb ceramic substrate.

The honeycomb substrate, also called support, is one of the components of the supported catalyst. The catalytically active component is supported on the surface of the carrier, the carrier is mainly used to support the active component, so that the catalyst has a specific physical property, and the carrier itself generally does not have catalytic activity.

Ceramic Honeycomb Substrate used in the catalytic converters have very low thermal expansion coefficient, high specific surface area, low pressure drop, rapid light-off and unique structures. Thousands of cells provide high surface for precious metal catalysts that convert noxious emission into water vapor, carbon dioxide and so on.

The honeycomb substrate is mainly used in the automotive and other high-temperature process exhaust. The main material is cordierite, after coated the catalyst, catalytic conversion of the exhaust, so as to achieve the national emission standards. It has characteristics of large surface area, small expansion coefficient, high strength, high water absorption, and good matching with the catalytic active component, heating up fast and so on.

Honeycomb ceramic as a Honeycomb Substrate is an efficient carrier and can achieve good results in specific applications. For example: photo-catalysis, fresh air system, ventilation systems.

Product size can be customized according to customer needs.

English

English Español

Español Français

Français Русский

Русский