Ceramic Foam Filter

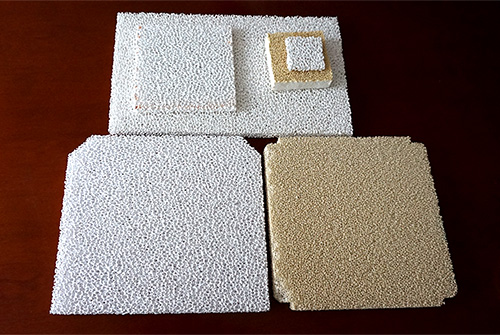

Ceramic foam can be divided into different materials such as alumina, silicon carbide, zirconia and others.

Ceramic foam filter is a kind of porous material with high temperature characteristics. Its pore size ranges from nanometer to micron, its porosity is between 20% and 95%, and its operating temperature is room temperature 1600°C. Due to its high porosity, high specific surface area, thermal shock resistance, high temperature resistance, chemical resistance, good mechanical strength, good filtration and adsorption properties, Ceramic Foam Filter can be widely used in heat exchange materials, cloth gas materials, automobile exhaust equipment, purification metallurgy, industrial filtration of molten metal, thermal energy recovery, light industrial spraying industry, industrial wastewater treatment, thermal insulation material, chemical Honeycomb Substrate. Ceramic Foam Filter have been used in automotive catalytic converters for a long time. The deodorant ceramic foam filter catalyst enables the catalytic combustion of organic solvents and malodorous gases in the waste water to achieve the purpose of deodorization and purification. The use of high-permeability Ceramic Foam Filter that are resistant to high temperatures and have sufficient thermal shock resistance can effectively remove high-temperature dust gases. In the process of urban sewage treatment, Ceramic Foam Filter also become one material for aeration treatment in urban sewage treatment.

Alumina ceramic foam filters are produced using advanced environmental protection technology, with high open porosity, uniform pore structure and high surface strength. Alumina ceramic foam filter is mainly used in aluminum and aluminum alloys and molten metal filtration below 1000°C. It can filter residues such as oxide slag, oxide scale, non-metallic inclusions and gate groove lining in molten metal efficiently which to solve the aluminum and aluminum alloy on the internal defect sensitivity problem.

- Technical Indicators:

Material |

Alumina |

Using Temperature |

≤1000℃ |

Colour |

White |

Pore size |

4~60 |

Porosity(%) |

80~90 |

RT Mpa |

≥1.4 |

Bulk Density |

0.35~0.50 |

Thermal Shock Resistance(time/1100°C) |

5 |

- Alumina Foam Filter:

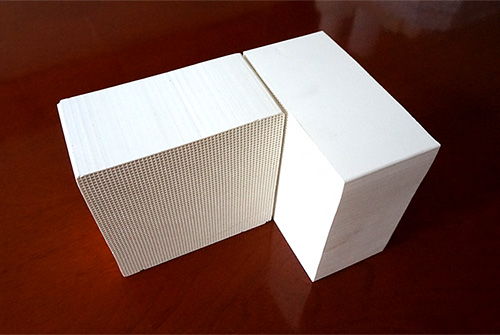

Ceramic foam filter is a kind of effective molten metal filter. It's three-dimensional connected mesh structure and high porosity has many advantages, for example, large surface area of slags collection, large inner surface area of filtering, small flow resistance, good filtering effect, etc.

- Physical and Chemical Properties:

Material |

Alumina |

Color |

White |

Pore Density |

8-60ppi |

Porosity |

80-90% |

Refractoriness |

≤1100℃ |

Bending Strength |

>0.6Mpa |

Compression Strength |

>0.8Mpa |

Volume-weight |

0.3-0.45g/cm3 |

Thermal Shock Resistance |

6times/1100℃ |

Application |

Aluminium, Aluminium alloys and other Non-ferrous alloys |

- Specification for Al2O3 Foam Filter:

Dimension (mm) |

Dimension (inch) |

Pouring Rate (kg/s) |

Filtration Capacity (ton) |

178*178*50 |

7*7*2 |

0.2-0.6 |

5 |

228*228*50 |

9*9*2 |

0.3-1.0 |

10 |

305*305*50 |

12*12*2 |

0.8-2.5 |

15 |

381*381*50 |

15*15*2 |

2.2-4.5 |

25 |

430*430*50 |

17*17*2 |

3.0-5.5 |

35 |

508*508*50 |

20*20*2 |

4.0-6.5 |

45 |

585*585*50 |

23*23*2 |

5.0-8.6 |

60 |

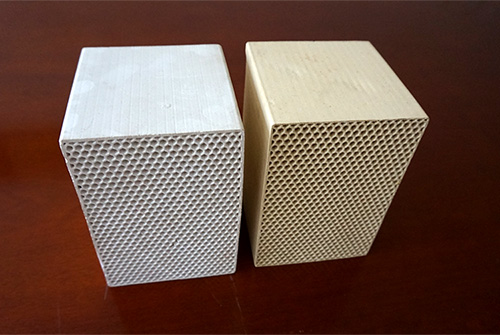

- SiC Carbide Foam Filter:

Functions of ceramic foam filter

Decontaminate the melting metal liquid

Simplified gating system

Improve the metallurgical structure of the castings

Reduce imparities of the castings

Improve casting quality rate

Reduce casting internal re-oxidation defects

Reduce the surface defects after machining of the castings

- Physical and Chemical Properties:

Material |

Silicon Carbide |

Color |

Grey Black |

Pore Density |

8-60ppi |

Porosity |

80-90% |

Refractoriness |

≤1500℃ |

Bending Strength |

>0.8Mpa |

Compression Strength |

>0.9Mpa |

Volume-weight |

0.35-0.5 g/cm3 |

Thermal Shock Resistance |

6times/1100℃ |

Application |

Ductile Cast Iron, Malleable Cast Iron, Gray ironand other Cast Iron |

- Specification for SiC Carbide Foam Filter:

Dimension (mm) |

Pouring Rate (kg/s) |

Filtration Capacity (ton) |

||

Grey Iron |

Ductile Iron |

Grey Iron |

Ductile Iron |

|

40*40*22 |

4 |

3 |

65 |

32 |

50*50*22 |

6 |

4 |

100 |

52 |

75*50*22 |

9 |

6 |

150 |

75 |

75*75*22 |

14 |

9 |

220 |

100 |

100*50*22 |

12 |

8 |

200 |

100 |

100*75*22 |

18 |

12 |

300 |

150 |

100*100*22 |

25 |

16 |

400 |

200 |

150*150*22 |

50 |

36 |

900 |

450 |

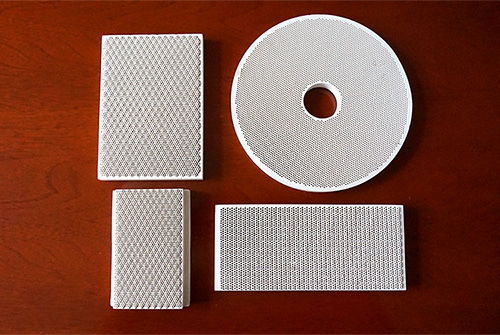

- Zirconia Foam Filter:

Foam ceramic filter have the characters of light, high strength, large specific surface area, high porosity, excellent heat resistance and chemical corrosion resistance. With the distributing pores net structure, they are able to increase the surface area, and absorb the thin waste, so the liquid metal can be molding safety. With the excellent characters, the Ceramic Foam Filter improve molding quality by reducing the reject probability of moldings and divide from that quality problem such as waste pore, sand pore and air pore. So that Ceramic Foam Filter are widely applied in the plant of nonferrous metal casting such as the casting of steel, iron, copper and aluminum.

The material of the Zirconia Ceramic Foam Filter is ZrO2. It is mainly used for purification process of steel and stainless steel production.

- Physical and Chemical Properties:

Material |

Zirconia |

Color |

Yellow |

Pore Density |

8-60ppi |

Porosity |

80-90% |

Refractoriness |

≤1700℃ |

Bending Strength |

>1.0Mpa |

Compression Strength |

>1.2Mpa |

Volume-weight |

0.9-1.5 g/cm3 |

Thermal Shock Resistance |

6times/1100℃ |

Application |

High melting point metal alloys like Steel, Alloy Steel, Stainless Steel etc |

- Specification for Zirconia Foam Filter:

Dimension(mm) |

Zirconia Foam Filter |

|

Pouring Rate(kg) |

Filtration Capacity(kg) |

|

50×50×22 |

3~5 |

30 |

50×75×22 |

4~6 |

40 |

75×75×22 |

7~12 |

60 |

75×100×22 |

8~15 |

80 |

100×100×22 |

14~20 |

100 |

Ф50×22 |

2~6 |

18 |

Ф80×22 |

6~10 |

50 |

Ф90×22 |

8~16 |

70 |

English

English Español

Español Français

Français Русский

Русский