Infrared Honeycomb Ceramic

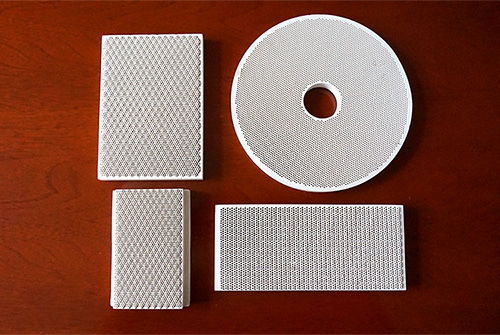

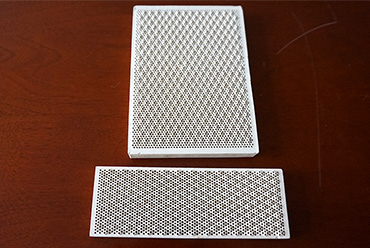

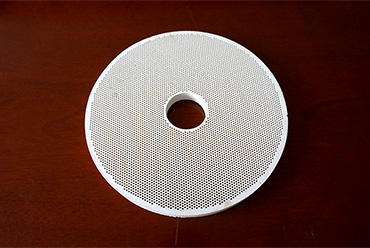

SANHE Infrared Ceramic Tile(Infrared Honeycomb Ceramic Plates) is cordierite based ceramic heating element.

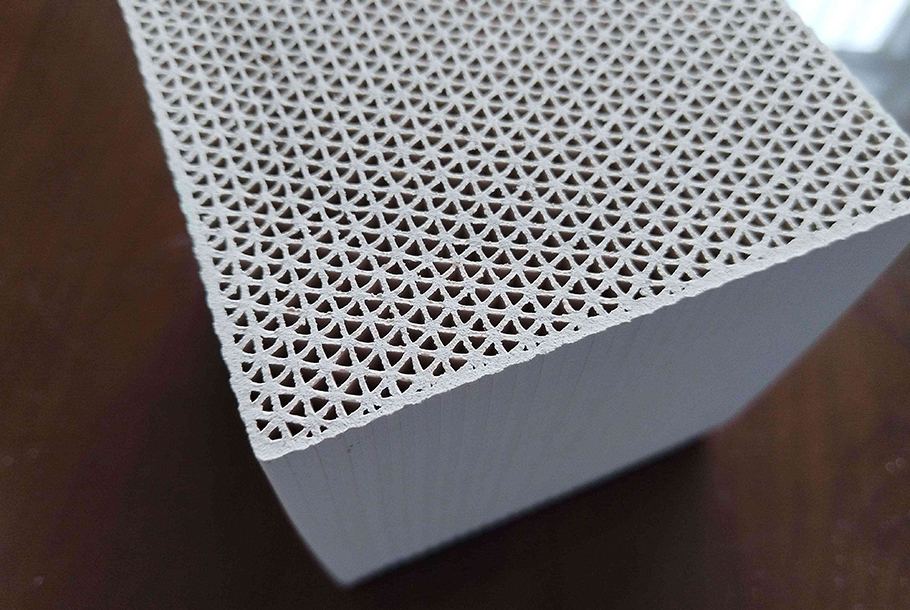

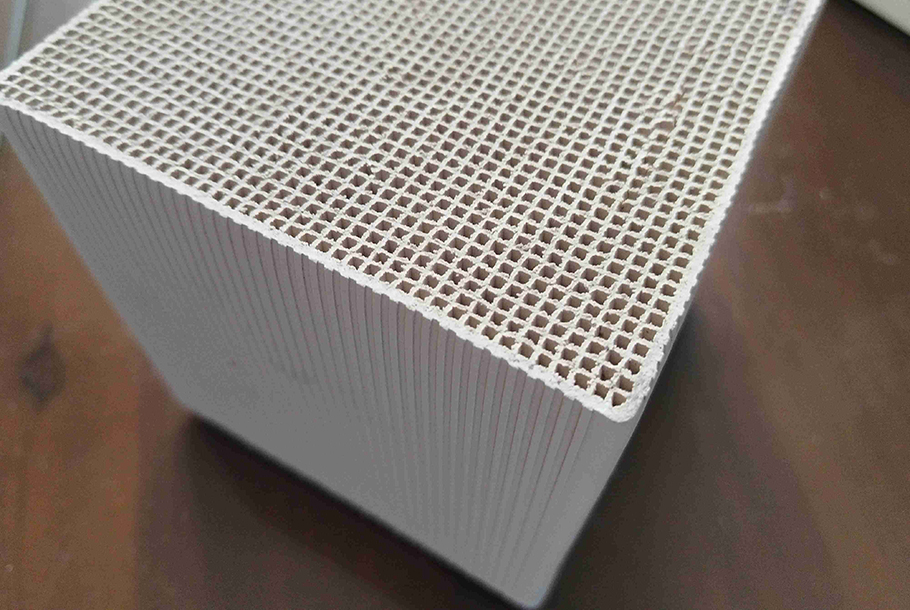

Infrared Ceramic Honeycomb Plates are widely used in gas radiant heaters and plays the most important part in those applications. The interlaced corrugated surface of the ceramic tile combined with honeycomb design basis provides a superb surface area and working burning surface. We have also adopted the best raw material and new formula to maximize the micro-porosity of the tile. With all these advantages, the oxygen mix completely with the gas, burning without flame, emitting high efficiency far infrared ray and radiant heat, saving up to 40-50% energy cost.

Our ceramic engineer has designed a unique manufacturing machine, which enables us to control the shape and the hole diameter to an enhanced precision level. After test on the real oven, the ceramic tile can generate uniform and high efficiency infra-red burning.

- Application:

Barbecues |

Gyro Cookers |

Broilers |

Pizza Ovens |

Convection Ovens |

Pressure Fryers |

Deep Fat Fryers |

Process |

Evaporators |

Ranges |

Gas Ovens |

Rotisserie Ovens |

Griddles |

Space Heaters |

Greenhouse CO2 |

Sear Cookers |

- Benefit:

1. Outstanding strength.

2. Uniform radiant burning.

3. Excellent thermal shock resistance.

4. Save up to 40~50% energy cost.

5. Burn without flame, high burning efficiency, low noise.

6. Reduce the harmful gas such as CO, NOx, etc more than 90%.

- Specification:

Sample Dimension |

||||

Square(mm) |

Round Shape Diameter (mm) |

Thickness (mm) |

Hole Diameter (mm) |

Holes Interval (mm) |

<180×180 |

50--200 |

8--15 |

1.2—1.8 |

1.649—2.086 |

Physical Properties |

||||

Porosity |

Density |

Coefficient of Thermal Expansion 0--800℃ |

Modulus of Rupture Results |

Thermal Shock 800℃ |

50%-60% |

≌1.2g/m3 |

3.5×10-6 |

≥300lbs/in2 |

More than 3 times Does not blast open |

Performance |

||||

Harmful Gas Release During Use |

|

|

||

Co |

≤0.006% |

|

|

|

NOx |

≤5ppm |

|

|

|

Nomal size: 132x93x12, Dia 144x12, Dia 148x12mm.

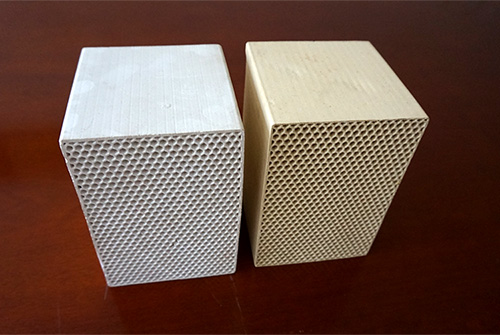

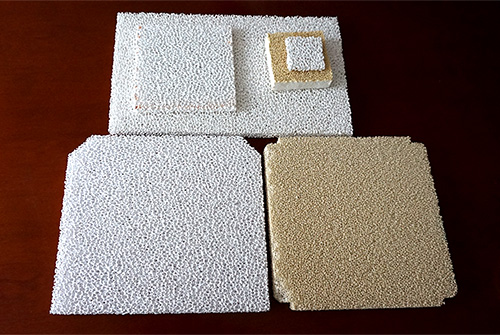

Infrared catalytic burner is a porous ceramic honeycomb panels attached to the catalyst as a burning stove, made use of advanced science and technology design. As a result of the ideal combustion - catalytic combustion of methane gas can be more fully combustion, maximize the energy of the gas, while also reducing flue gas pollution (CO < 0.02% of NOx < 10 ppm), completely to meet national environmental standards; catalytic combustion but also to eliminate the infrared combustion prone to coking phenomenon, to effectively extend the life of the burner; our catalytic combustion in the hole of the porous ceramic honeycomb board, it is true flameless combustion, produce most of the energy released in the form of infrared radiation, infrared has a strong penetration can stimulate the resonance of water molecules, so that the heat to penetrate into the depths of the object to be heated evenly. in order to ensure uniform heating effect to achieve the purpose to improve the heating quality and drying efficiency.

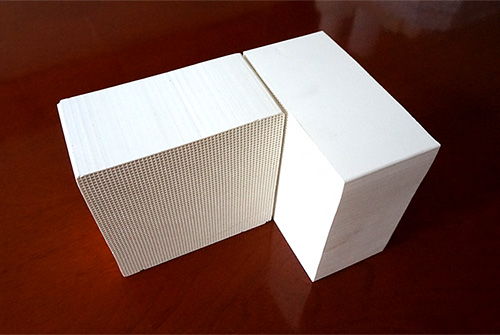

Infrared Honeycomb Ceramic Plate, mainly for gas-fired infrared burners. Such a ceramic plate by honeycomb ceramic plate surface to improve the simple planar corrugated staggered three-dimensional, increasing the specific surface area and combustion area, which play a regenerative combustion role to achieve more complete combustion flame seedlings to reach the infrared burner heating effect, in order to achieve low power consumption and high environmental requirements. Overcome the planar flame in the combustion of the gas is too long, burning inadequate, resulting in high energy consumption, emissions low enough to deficiencies.

- Characteristics:

1. Use of liquefied petroleum gas, clean, environmentally friendly.

2. High thermal efficiency, economical and practical, the cost of gas consumption than the power consumption savings of 50%.

3. Install a convenient and simple. Compared with the electric dryer, reduce costs by more than half.

Therefore, using the infrared burner has become the industrial heating, drying, thermal insulation of a new technology, new vigorous, it has been widely used in industrial paint, printing and dyeing, food and other industries and fields.

- Typical Applications:

1. Bake furnace.

2. Food baking production line computer automatic dryer.

3. Dedicated gas infrared oven.

4. Food grilled cabinet.

5. Food baking line.

6. Spray the bottom of the production line installation.

We produce honeycomb ceramic infrared radiation effect, high strength, combustion does not change color, not coke, burning fireworks hole to plug, no glitches, uniform pore size, ignition and burning half a minute into the infrared effects, ceramic burning a hours after watering not rupture, the burning area established by the BTU.

- Technical Parameters:

Property |

Value |

Density g/cm3 |

0.6-0.7 |

Water absorption |

40-50% |

Flexural strength kgf/cm2 |

10-20 |

Coefficient of thermal expansion 10-6/K |

1.5-2 |

Thermal conductivity W/(m.K) |

1.1-1.3 |

Maximum use temperature ℃ |

1200 |

Thermal shock performance (20-1000 °C) |

No crack 10 times |

English

English Español

Español Français

Français Русский

Русский