Honeycomb Blocks For Heater Exchanger

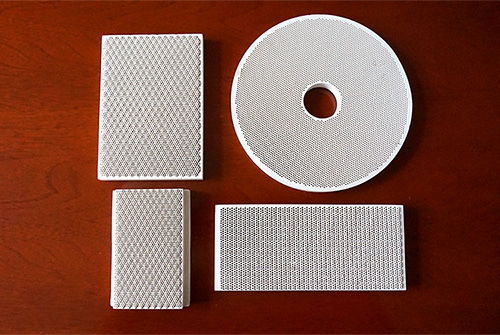

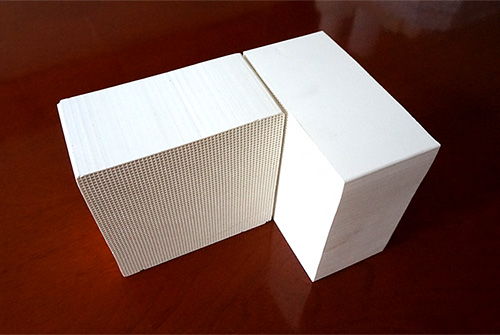

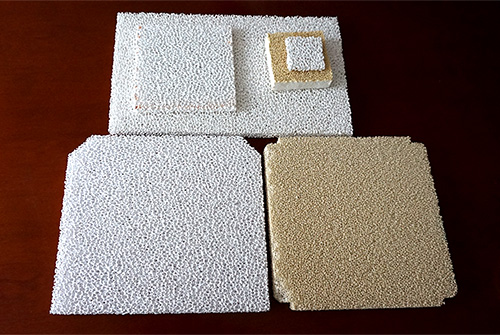

Ceramic honeycomb blocks are used as heat exchanger material in regenerative thermal oxidizers (RTO's). RTO's are capable of extremely high thermal efficiencies up to 97%. When considering a replacement oxidizer, RTO's can cut the customer's gas cost considerably making the switch an easy decision. Due to their high thermal efficiency, Regenerative Thermal Oxidizers can often go into "self-sustain" mode, in which the burner shuts off completely, using zero gas. Longevity is also another big advantage for the RTO, because the heat exchanger and combustion zone are internally lined with refractory insulation. There are no internal steel components which are exposed to reaction chamber temperature. RTO's can achieve high thermal efficiencies due to the ceramic media. Each process is evaluated by our engineers to determine the correct media for the application. We utilize either structured (honeycomb) media or random packed media in the RTO design, depending on the application.

English

English Español

Español Français

Français Русский

Русский