- Home

- Products

- Supporting Equipment

- Heat Exchanger

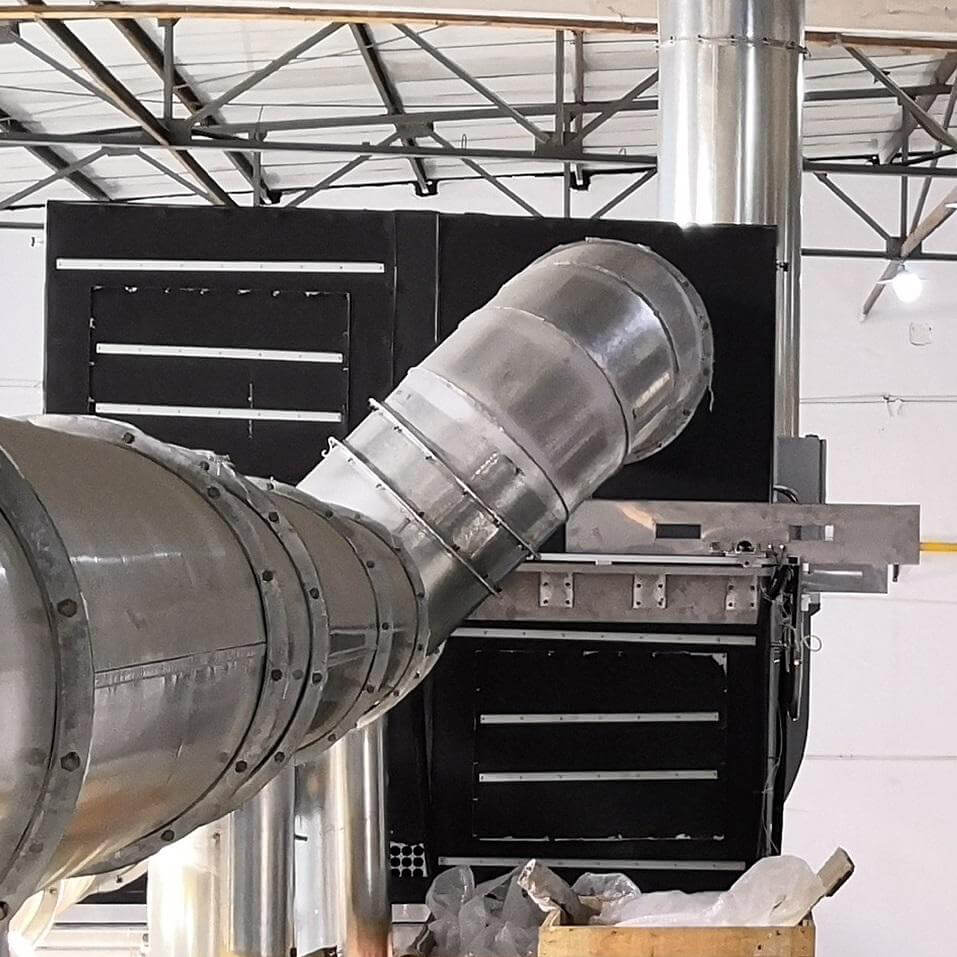

Heat Exchanger

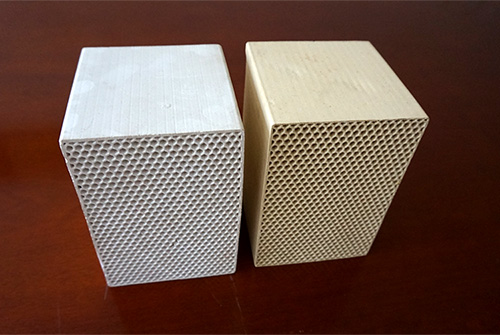

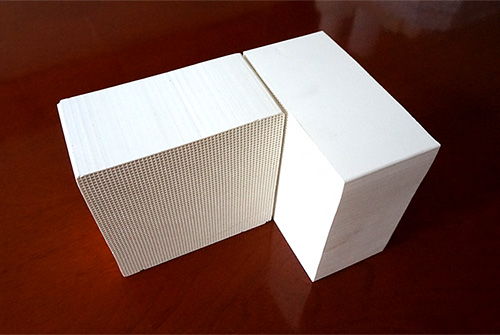

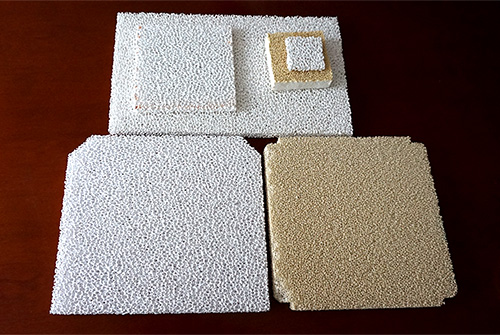

Sanhe develops and produces straight-hole ceramic gas heat exchangers below 1000℃, which are used in boiler flue gas heat exchangers, denitrification flue gas energy saving, coke oven flue gas waste heat recovery, rotary kiln flue gas heat recovery, glass kiln flue gas heat recovery, combustion furnace flue gas heat recovery, boiler air preheater, air preheater, denitrification energy saving, dewhitening, desulfurization and dewhitening, RTO energy saving, CO energy saving, catalytic oxidation heat exchanger, oven energy saving, printing machine energy saving, coating machine energy saving, dipping machine energy saving, setting machine exhaust gas energy saving, dryer energy saving, heat pump drying energy saving, deodorization and cooling, animal room fresh air energy saving, air conditioning fresh air energy saving, cold storage energy saving, VOCs condensation recovery and other industries.

- Features:

1, Compared with the rotary heat exchanger, the double-box flue gas heat exchanger can adapt to higher temperatures, withstand 6000P wind pressure, is corrosion-resistant, and is suitable for more industrial fields.

2, The ventilation volume can be different capacities from 300m3/h to 300,000m3/h, and the discharge can be the same as the recovery air volume.

3, Adapt to high temperature resistance; ultra-low temperature resistance; corrosion resistance; tolerance to condensed water, anti-clogging; can provide a stable latent heat recovery temperature.

4, Adapt to heat exchange between high-pressure gases greater than 6000Pa.

5, Adopt zero-leakage sealed lifting valve, the switching speed is as fast as 1S, the life is more than 1 million times, the cost is low, and the maintenance is simple.

- Four advantages of ceramic heat exchange

The heat storage performance is stable, the equipment structure is compact, it is suitable for high-temperature and low-temperature exhaust gases, and the cost is low.

NO.1 Standard modular design

It can be flexibly controlled according to user working conditions, reduce investment and ensure stable operation.

NO.2 Easy to use

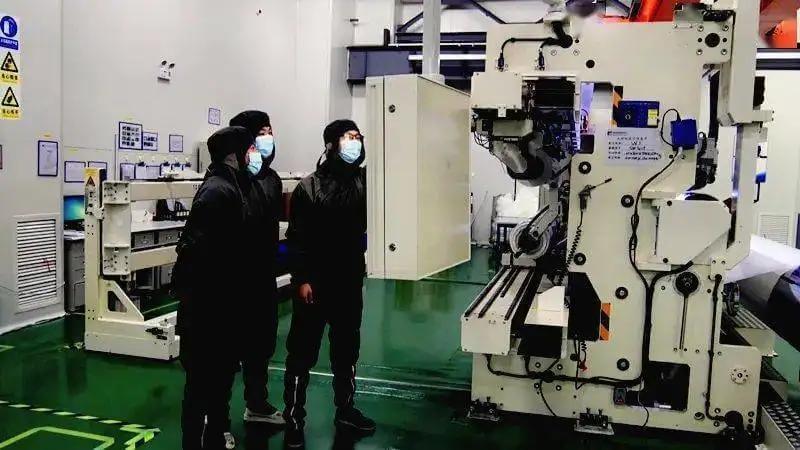

The operation is simple, it adopts famous brand control components and systems, and has a high degree of automation; it can be operated immediately.

NO.3 Excellent technology

It adopts thermal storage ceramics for heat exchange, which can be applied to any oxidation and corrosion conditions and occupies a small area.

NO.4 Energy-saving and efficient

Can be unattended, heat recovery rate is over 75%-85%, energy-saving utilization.

- Application:

It is suitable for various heating furnaces, hot air furnaces, heat treatment furnaces, cracking furnaces, roasters, condensing furnaces, soaking furnaces, oil and gas boilers and other kilns in the steel, machinery, power generation, building materials, chemicals, petrochemicals, coatings, non-ferrous metal smelting and other industries, RTO, and high-temperature exhaust gas waste heat recovery.

English

English Español

Español Français

Français Русский

Русский