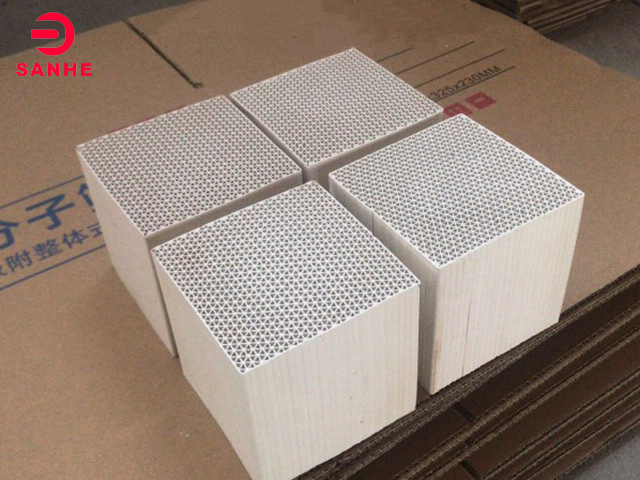

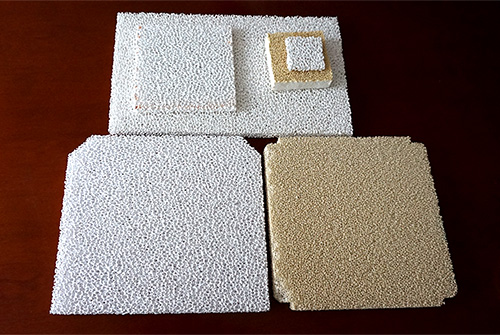

Honeycomb Ceramic Molecular Sieve

- Introduction for Honeycomb Ceramic VOC Dewatering Molecular Sieve:

At present, VOCs treatment mainly uses activated carbon. Since activated carbon cannot be analyzed at high temperature, thus it should be replaced regularly. However, activated carbon adsorbed with organic matter is a dangerous chemical with high processing cost. This environmentally friendly adsorbent material is hydrophobic molecular sieve, which is different from ordinary molecular sieve in that it preferentially adsorbs water in gas. It has a highly selective adsorption capacity for organic matter, and can be resolved at high temperature, thus realizing continuous adsorption-regeneration. The adsorption material is made into a cellular structure by a special preparation process. The adsorption capacity of organic matter is more than 90%, which can be adsorbed and regenerated for a long time.

- The honeycomb zeolite which produced by Sanhe Group has the following advantages:

1. Strong adsorption selectivity: According to different components of organic waste gas, the products are equipped with molecular sieve materials with different properties and pore size, so as to achieve targeted and selective treatment of organic waste gas, meet the design requirements and emission standards.

2. Strong adsorption capacity: Even if the composition concentration of the gas is very low at mg level, it still has adsorption capacity.Compared with similar activated carbon to improve the efficiency of 50%.

3. Wide adaptability of adsorption temperature: The adsorption capacity of zeolites is still relatively high even at higher temperature, while other adsorbents are greatly affected by temperature. Therefore, the adsorption capacity of zeolite is large at the same temperature.

4. Good regenerative temperature resistance: After adsorption and concentration by molecular sieve, the concentration factor of pollutants can be up to 15 times to 20 times. After concentration, the waste gas can be condensed and recycled or processed by high temperature combustion as required.

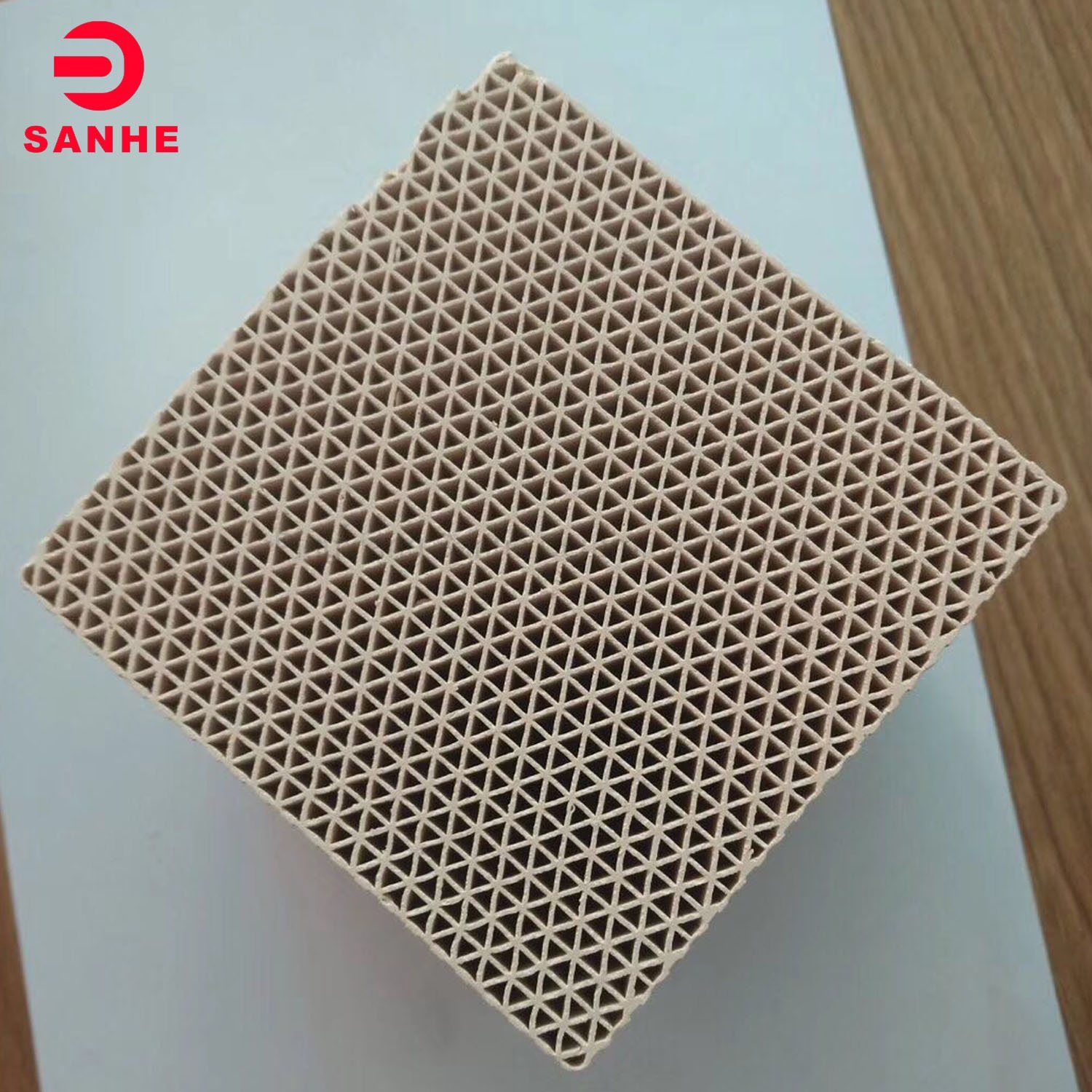

5. High strength: Using special skeleton materials, so that the honeycomb zeolite positive compressive strength can be more than 3Mpa, to reduce damage during transportation and installation.

- Technical Index:

| Performance | Micropore |

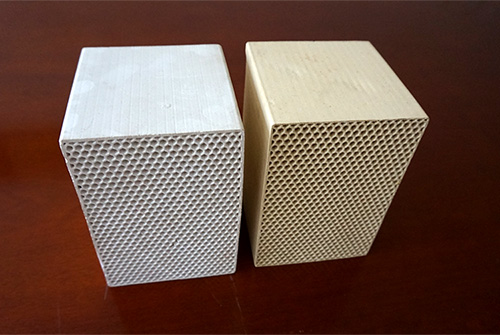

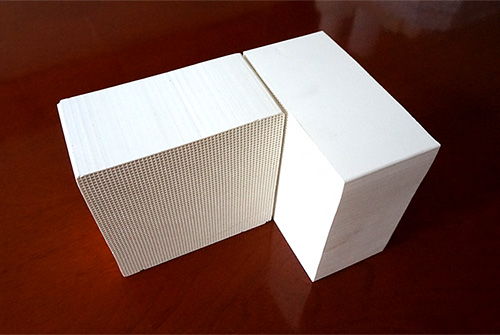

| Dimensions | 100*100*100-100W 100*100*50-50W |

| Mesh NO. | 100 |

| Wall Thickness | 0.4mm |

| Positive Compressive Strength | >3.0 Mpa |

| Volume-Weight | <400 g/L |

| Specific Surfance Area | >900 m2//g |

| Purifying Efficiency | >90% |

| Thermal Resistance | >900 degree |

| Lifetime | >2 years |